About us

ShowTex is a worldwide leader in inventing, manufacturing and installing innovative flame retardant fabrics, tracks and motion control systems for achieving the creative vision of theatre, event and entertainment professionals.

Puy du Fou has been elected best theme park of the world as a reward for its originality and uniqueness. You can choose from a wide and permanently diversified array of shows recreated in a life-sized setting taking young and old on an adventure. The teams of the big park were ardent to set up the biggest original creation of the history of Puy du Fou: Le Dernier Panache!

The combined history of Puy du Fou and ShowTex dates already back to more than 10 years. Together, we designed and installed the biggest stage curtain in the world on a track system of the ChainTrack type, mounted a Roman curtain of 71 m made of GobelinTulle on an ultra-fast HiSpeed Roll-Up 8000 system that lifts the curtain at a rate of 1.5 m per second…

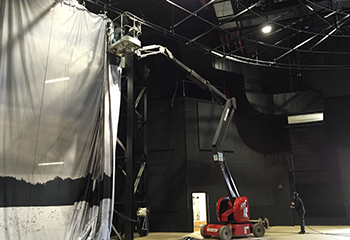

In 2016, ShowTex material was used to produce the drapes, prints, screens, structures and stage mechanisms for Le Dernier Panache, the new original creation of Puy du Fou, a show that is even bigger than ever before. A first for all of us!

The installation of the ShowTex material in only a few weeks’ time owes its success to the substantial stocks, the large-scale workshops, the many specialised technicians (all the riggers, mountaineers, sewers, installers) and the total involvement of the project managers as well as the head of the installation team who have accumulated years of experience in this field. Days and nights, 24/7, the teams rotated shifts to achieve the most realistic and unique rendition!

"This was probably the biggest project that I have realised in such a short time. There are not enough superlatives to describe this job. I am very happy that I had been part of this production, which I will never forget." (Installation Manager)

Nicolas de Villiers – president and artistic director of Puy du Fou in charge of the new show – pictured a precise and structured scenery, setting high standards to the choice of materials to be used. The ShowTex team was able to offer solutions meeting all requirements in accordance with the mandatory standards. The curtains as well as the tracks were self-evident, leaving little room for uncertainty: solid and sturdy material suitable for intensive use at the big theme park of Puy du Fou and the numerous shows a day.

Nicolas de Villiers – president and artistic director of Puy du Fou in charge of the new show – pictured a precise and structured scenery, setting high standards to the choice of materials to be used. The ShowTex team was able to offer solutions meeting all requirements in accordance with the mandatory standards. The curtains as well as the tracks were self-evident, leaving little room for uncertainty: solid and sturdy material suitable for intensive use at the big theme park of Puy du Fou and the numerous shows a day.

To highlight the scenery and create a mood that matches the theme of the show, the masking drapes hanging at the 6 scenic spaces were made of Molton CS – without risking the loss of the highest French M1 standard in a sometimes humid environment.

Borders with a length of more than 60 metres, Italian and German style stage curtain legs, backdrops, lining of printed fabrics… account for more than 1 ton in total and 700 linear metres of borders!

Borders with a length of more than 60 metres, Italian and German style stage curtain legs, backdrops, lining of printed fabrics… account for more than 1 ton in total and 700 linear metres of borders!

To create an immersive environment and the largest projection surface possible, the cyclorama displaying the sea is a giant panoramic screen made of FP SuperMat with a high light output. It measures not less than 80 m in width by 11 m in height. The primary aim was to not lose a single centimetre and to get as close to the roof structure as possible. Therefore, a tube was custom curved and attached to the bottom of a steel profile that was directly clamped to the bottom of the H beams.

Giant Screen

While the bottom of the screen is immersed in water and hit by the waves during the show, the bottom finishing has to keep the screen perfectly still during the projection. This finishing consists of an open tube with curved weight pipes under which a removable flap is attached. Weighted with a stainless steel chain immersed in the water, the screen remains nice and tight, while the flap absorbs the shocks of the waves against the screen.

While the bottom of the screen is immersed in water and hit by the waves during the show, the bottom finishing has to keep the screen perfectly still during the projection. This finishing consists of an open tube with curved weight pipes under which a removable flap is attached. Weighted with a stainless steel chain immersed in the water, the screen remains nice and tight, while the flap absorbs the shocks of the waves against the screen.

Only requiring one week to produce and 10 hours to install (even though the basin was already filled with water during the set up), this screen represents one of the showpieces of the installation by ShowTex for Le Dernier Panache.

Prints

This scene presented a new challenge for Puy du Fou/ShowTex. A real, life-size palace appears when the curtain half-opens. This scenery required an incredible level of precision to achieve enhanced realism: printing on Galaxy 250 Print was the solution. This M1-certified soft material renders the desired result.

This scene presented a new challenge for Puy du Fou/ShowTex. A real, life-size palace appears when the curtain half-opens. This scenery required an incredible level of precision to achieve enhanced realism: printing on Galaxy 250 Print was the solution. This M1-certified soft material renders the desired result.

Traditional printing would however have been too simple. The ShowTex sewers have done sterling work, hot cutting the smallest details from the windows to allow mirror effects behind the prints.

"We started the Showtex adventure 10 years ago with the curtain for Grand Carrousel. Ever since, the craziest projects followed in rapid succession, such as a 71 m long HighSpeed scrim. We could not resist to present this challenge to the ShowTex team who once again rose to the challenge of Théâtre des Géants." (Steven Barthelemy - technical manager of Dernier Panache)

All elements, small pieces of wood, frames and locking rods were hand sewn on LaserVoile intended to guarantee that all cut-out details remain firmly in place while being 99% invisible. Since the same scenic space had to be used for several scenes of the show, the two printed backdrops of 200 m² were equipped with a HiSpeed Roll-Up 8000 system as well as a mechanism at the back for Roman curtain opening allowing the set to be changed, all controlled by DMX.

All elements, small pieces of wood, frames and locking rods were hand sewn on LaserVoile intended to guarantee that all cut-out details remain firmly in place while being 99% invisible. Since the same scenic space had to be used for several scenes of the show, the two printed backdrops of 200 m² were equipped with a HiSpeed Roll-Up 8000 system as well as a mechanism at the back for Roman curtain opening allowing the set to be changed, all controlled by DMX.

The aim was to achieve total realism: Puy du Fou is above all a theme park hosting live shows with real actors and sets taking the spectators on a journey through time.

2 Roman-Style Curtain Opening Systems of 21 m

The HiSpeed Roll-Up 8000 system (2 units of 21 m), ideal to realise Roman-style opening mechanisms, was chosen for its high speed and DMX controller, but even more so for its sturdiness, the reliability of the system, its ease of assembly and maintenance.

The HiSpeed Roll-Up 8000 system (2 units of 21 m), ideal to realise Roman-style opening mechanisms, was chosen for its high speed and DMX controller, but even more so for its sturdiness, the reliability of the system, its ease of assembly and maintenance.

Here again, the small number of attachment points required was an advantage – which cannot always be planned in advance in the final stage of a structure.

2 Concentric Motorised Tracks of 31 m

The masking drapes and the printed curtains were attached to concentric ShowTrack tracks each with a length of 31 m.

The choice was made based on its characteristics: the full extruded aluminium profile (50 mm x 100 mm) resists very high point loads, requires less attachment points, is very silent and is equipped with a built-in Rope Drive motor for easy and efficient DMX or quite simple cable control.

"The challenge was enormous as it has always been the case at Puy du Fou and will remain etched in our memories. The experience was enriching for everyone who was involved in the project. This type of job reminds us that each link in the production chain is essential. For me, this proved once again that for ShowTex the sky is the limit!" (Project Manager)

The teams installed false grilles above 4 of the 6 stages: a necessary system which can be hidden easily for hanging draperies, printed curtains, light sources and other elements that are essential for this highly technical scenography. On two of the six stages, where the height of certain decorative elements did not allow the installation of borders, the use of StretchTulle quickly became a matter-of-course. Stretch ceilings mounted in complex frames hanging at different heights above the same stage can be used to create the illusion of a closed – but flexible – black ceiling.

The teams installed false grilles above 4 of the 6 stages: a necessary system which can be hidden easily for hanging draperies, printed curtains, light sources and other elements that are essential for this highly technical scenography. On two of the six stages, where the height of certain decorative elements did not allow the installation of borders, the use of StretchTulle quickly became a matter-of-course. Stretch ceilings mounted in complex frames hanging at different heights above the same stage can be used to create the illusion of a closed – but flexible – black ceiling.

350 m² of ceiling per stage, in a multitude of different shapes, are supported by a grid of black sheathed cables to guarantee that no sagging occurs.

Flexible Mobile M0 Screens

The initial idea of the Grand Parc was to install several sturdy mobile panels to set up this projection surface that sometimes moves with a speed of 120 cm/second. For practical reasons (weight, installation, etc.) a more suitable solution arose: to make the screens from soft material.

The initial idea of the Grand Parc was to install several sturdy mobile panels to set up this projection surface that sometimes moves with a speed of 120 cm/second. For practical reasons (weight, installation, etc.) a more suitable solution arose: to make the screens from soft material.

The challenge was not easy: these projection surfaces also serve as separation curtains to close off the public areas in case of fire. The only material accepted by the safety commission for this purpose was fibreglass, a non-flammable material of the French FR class M0. After consultation and several projection tests, one material appeared to be the most consistent: FiberCloth M0.

A novelty for ShowTex! This material appeared to be the least reflective, offering the best rendition of the projected images as well as great flexibility. More than 1700 m² of M0 fabric were produced for this project, accounting for more than 1.7 ton…

A second layer of fibreglass but this time of a grey colour was used as a lining for the white fibreglass: the principal aim was to have a unique projection surface with no visible lines between the different screens. The final result were screens measuring 22 m in length by 11 m in height, weighing 250 kg per unit of fabric, brought to the set on rolls of 12 m by means of special transportation fit for confined and hard to reach spaces. Two technicians from the ShowTex workshop had to come over for this special mission of the assembly on site that took 2 to 3 weeks.

This astonishing performance uses 7 screens that move with a speed of 1.2 m per second offering the biggest possible projection surface, while maintaining the flexibility required to reveal the different scenes with their real-life scenery.

To achieve total immersion, a piece of fabric was cut in the shape of a giant lamp shade to add extra projection surface measuring almost 4 m high by 150 m long. This black backdrop was printed and stretched perfectly nice and tight.

To achieve total immersion, a piece of fabric was cut in the shape of a giant lamp shade to add extra projection surface measuring almost 4 m high by 150 m long. This black backdrop was printed and stretched perfectly nice and tight.

The sound source was mostly installed behind fabric. Therefore, the choice of New Mesh was obvious: a sound-permeable, flame-retardant, printable, durable material that resists humid environments and can be stretched wonderfully.

One of this project’s challenges was the time available: the entire structure had to be installed in only a few months’ time. All specialised teams had to work together and at the same time while real-time adjustments to the plans and the measures were required. As is often the case, the complexity also resided in the coordination of the different teams: installation of the stand, mounting of the lights, fresh paint, closed access doors and all other simultaneous assembly operations had been a real challenge for all teams working on the same project!

One of this project’s challenges was the time available: the entire structure had to be installed in only a few months’ time. All specialised teams had to work together and at the same time while real-time adjustments to the plans and the measures were required. As is often the case, the complexity also resided in the coordination of the different teams: installation of the stand, mounting of the lights, fresh paint, closed access doors and all other simultaneous assembly operations had been a real challenge for all teams working on the same project!

*These are non-standard products. Contact your local office for more information.